- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Are you troubled by low efficiency and 3%–5% defect rates caused by manual heat shrink baking or single-station equipment? Traditional devices can only process less than 500 pieces per shift, which severely limits your production line capacity. Our Heat Shrink Tube Baking Machine breaks through these limitations with innovative technology, realizing high-efficiency, precision, and stable wire harness processing for your business.

Equipped with an innovative matrix heating module, this machine can bake 20+ heat shrink tubes (diameter 5–20mm) at the same time. Compared with traditional single-station equipment, it boosts production efficiency by 20 times, with a single-shift capacity exceeding 10,000 pieces. This batch processing capability directly transforms your production mode from single manual operation to batch automation, driving a leap in production line capacity.

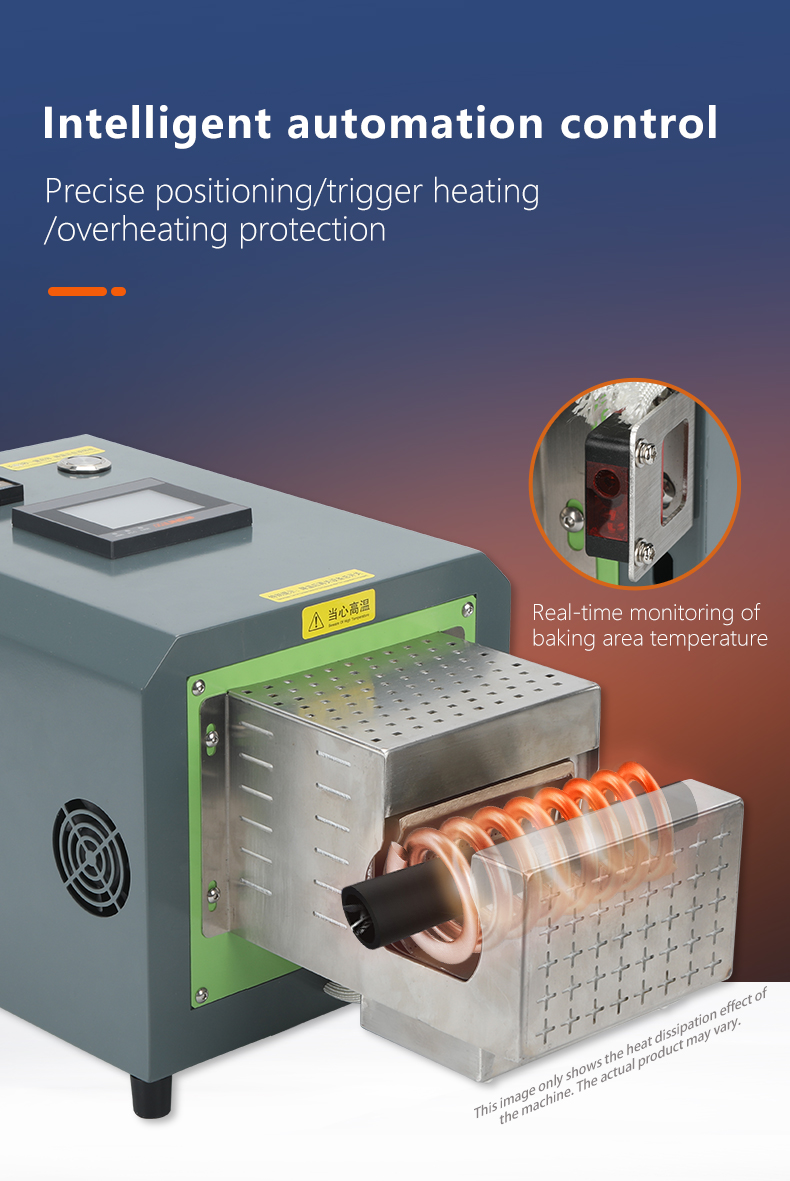

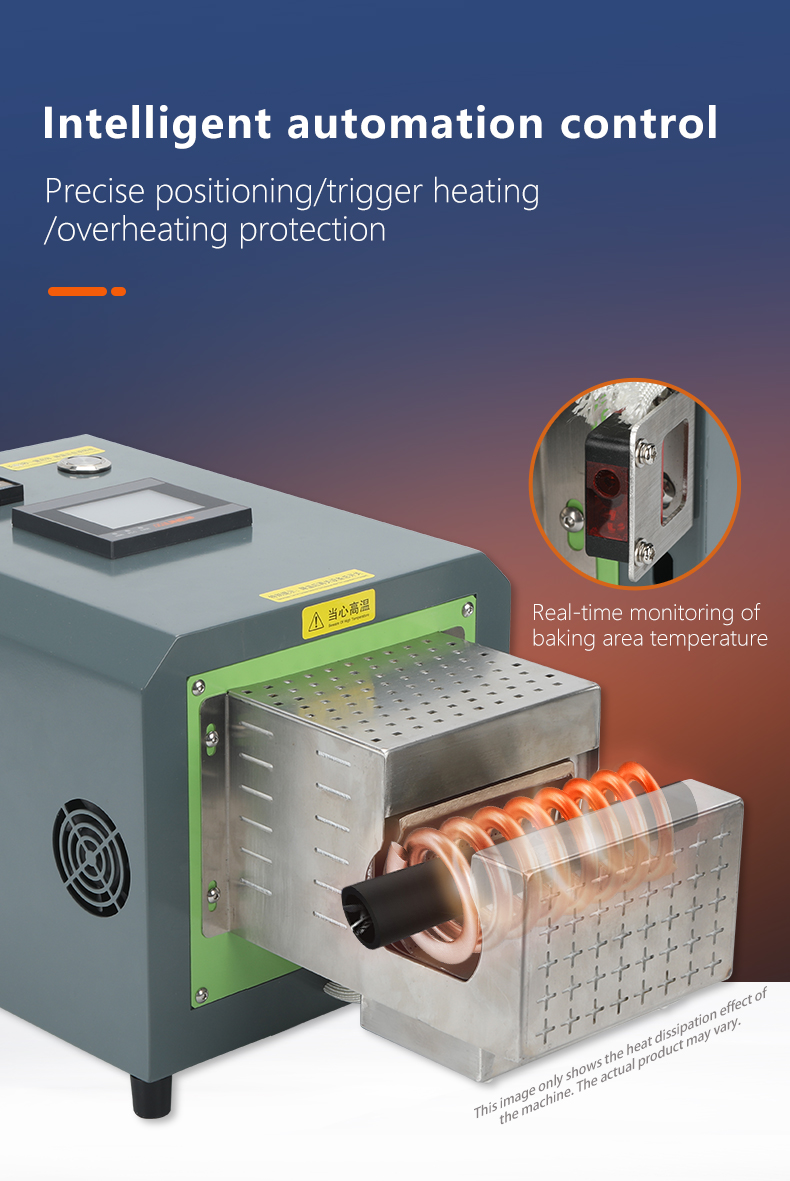

The Heat Shrink Tube Baking Machine is fitted with high-precision temperature sensors and a PLC-controlled baking system, which monitors the heating zone temperature in real time with ±1℃ accuracy. It strictly maintains the optimal heating range of 80–150℃ for heat shrink tubes, ensuring uniform heating of each workpiece. This precision control effectively eliminates common problems such as tube cracking and insufficient shrinkage, reducing the defect rate to below 0.5%.

We provide customizable fixtures that are compatible with round, flat, and other special-shaped wire harnesses. This flexible design makes the machine suitable for diverse production scenarios in electronics, automotive, new energy, and smart home industries. Whether you process automotive electronic wire harnesses or new energy battery pack harnesses, this equipment can perfectly match your production requirements.

The machine is equipped with a touchscreen visual interface, allowing new operators to set parameters easily without complicated training. It also supports real-time operation status display and automatic fault alarm functions, which can quickly locate problems and reduce maintenance costs. This humanized design greatly improves the daily operation efficiency of the equipment.

Specification Item | Details |

Machine Type | Industrial Heat Shrink Tube Baking Machine |

Heating Method | Matrix Heating Module (Synchronous Multi-station) |

Temperature Control Precision | ±1℃ (Real-time Monitoring) |

Optimal Heating Range | 80–150℃ (Suitable for Most Heat Shrink Tubes) |

Processable Tube Diameter | 5–20mm |

Number of Stations | 20+ (Customizable) |

Single-shift Capacity | ≥10,000 Pieces |

Control System | PLC-controlled Baking System |

Operation Interface | Touchscreen Visual Interface |

Fixture Compatibility | Customizable (Fits Round, Flat & Special-shaped Wire Harnesses) |

The multi-station synchronous heating design realizes a 20x efficiency improvement compared with traditional equipment. It helps your production line get rid of the bottleneck of low efficiency and achieve large-scale batch production.

Uniform heating technology and precise temperature control ensure the consistency of each heat shrink tube processing. It enhances the reliability of your wire harness products and helps you win more market recognition.

This equipment reduces labor input by 80% and cuts down rework costs caused by defective products. Its high cost-performance ratio enables you to recover the equipment investment quickly.

Automotive Electronics: Process automotive electronic wire harnesses to meet the high-standard requirements of the automotive industry.

New Energy: Handle new energy battery pack harnesses, adapting to the strict production standards of the new energy field.

Smart Home: Process smart home connection harnesses, matching the diversified needs of smart home product production.

Industrial Control: Process industrial control equipment harnesses, ensuring the stability and safety of industrial control systems.

Our Heat Shrink Tube Baking Machine has an optimal heating range of 80–150℃, which is suitable for most standard heat shrink tubes. Equipped with a PLC-controlled baking system, it can also adjust the temperature slightly according to your specific tube material needs, ensuring perfect shrinkage effect every time.

The machine is designed to process heat shrink tubes with a diameter of 5–20mm, which covers the most common sizes in automotive, new energy, and smart home wire harness processing. If you need to process tubes of other sizes, we can provide customizable solutions to meet your production needs.

Absolutely. The machine is equipped with a touchscreen visual interface, which allows new operators to master parameter setting and operation in a short time without complicated training. It also has real-time operation status display and automatic fault alarm functions, greatly reducing operation and maintenance difficulty.

Yes. We offer customizable fixtures that are compatible with round, flat, and various special-shaped wire harnesses. Whether you have special production requirements for automotive electronic harnesses or new energy battery pack harnesses, our team can design matching fixtures to ensure the machine fits your production line perfectly.

Thanks to the ±1℃ precision temperature control and uniform matrix heating module, the defect rate of our Heat Shrink Tube Baking Machine is controlled below 0.5%, which is much lower than the industry average (3%–5%). This can effectively reduce rework costs and improve your production efficiency.

Are you troubled by low efficiency and 3%–5% defect rates caused by manual heat shrink baking or single-station equipment? Traditional devices can only process less than 500 pieces per shift, which severely limits your production line capacity. Our Heat Shrink Tube Baking Machine breaks through these limitations with innovative technology, realizing high-efficiency, precision, and stable wire harness processing for your business.

Equipped with an innovative matrix heating module, this machine can bake 20+ heat shrink tubes (diameter 5–20mm) at the same time. Compared with traditional single-station equipment, it boosts production efficiency by 20 times, with a single-shift capacity exceeding 10,000 pieces. This batch processing capability directly transforms your production mode from single manual operation to batch automation, driving a leap in production line capacity.

The Heat Shrink Tube Baking Machine is fitted with high-precision temperature sensors and a PLC-controlled baking system, which monitors the heating zone temperature in real time with ±1℃ accuracy. It strictly maintains the optimal heating range of 80–150℃ for heat shrink tubes, ensuring uniform heating of each workpiece. This precision control effectively eliminates common problems such as tube cracking and insufficient shrinkage, reducing the defect rate to below 0.5%.

We provide customizable fixtures that are compatible with round, flat, and other special-shaped wire harnesses. This flexible design makes the machine suitable for diverse production scenarios in electronics, automotive, new energy, and smart home industries. Whether you process automotive electronic wire harnesses or new energy battery pack harnesses, this equipment can perfectly match your production requirements.

The machine is equipped with a touchscreen visual interface, allowing new operators to set parameters easily without complicated training. It also supports real-time operation status display and automatic fault alarm functions, which can quickly locate problems and reduce maintenance costs. This humanized design greatly improves the daily operation efficiency of the equipment.

Specification Item | Details |

Machine Type | Industrial Heat Shrink Tube Baking Machine |

Heating Method | Matrix Heating Module (Synchronous Multi-station) |

Temperature Control Precision | ±1℃ (Real-time Monitoring) |

Optimal Heating Range | 80–150℃ (Suitable for Most Heat Shrink Tubes) |

Processable Tube Diameter | 5–20mm |

Number of Stations | 20+ (Customizable) |

Single-shift Capacity | ≥10,000 Pieces |

Control System | PLC-controlled Baking System |

Operation Interface | Touchscreen Visual Interface |

Fixture Compatibility | Customizable (Fits Round, Flat & Special-shaped Wire Harnesses) |

The multi-station synchronous heating design realizes a 20x efficiency improvement compared with traditional equipment. It helps your production line get rid of the bottleneck of low efficiency and achieve large-scale batch production.

Uniform heating technology and precise temperature control ensure the consistency of each heat shrink tube processing. It enhances the reliability of your wire harness products and helps you win more market recognition.

This equipment reduces labor input by 80% and cuts down rework costs caused by defective products. Its high cost-performance ratio enables you to recover the equipment investment quickly.

Automotive Electronics: Process automotive electronic wire harnesses to meet the high-standard requirements of the automotive industry.

New Energy: Handle new energy battery pack harnesses, adapting to the strict production standards of the new energy field.

Smart Home: Process smart home connection harnesses, matching the diversified needs of smart home product production.

Industrial Control: Process industrial control equipment harnesses, ensuring the stability and safety of industrial control systems.

Our Heat Shrink Tube Baking Machine has an optimal heating range of 80–150℃, which is suitable for most standard heat shrink tubes. Equipped with a PLC-controlled baking system, it can also adjust the temperature slightly according to your specific tube material needs, ensuring perfect shrinkage effect every time.

The machine is designed to process heat shrink tubes with a diameter of 5–20mm, which covers the most common sizes in automotive, new energy, and smart home wire harness processing. If you need to process tubes of other sizes, we can provide customizable solutions to meet your production needs.

Absolutely. The machine is equipped with a touchscreen visual interface, which allows new operators to master parameter setting and operation in a short time without complicated training. It also has real-time operation status display and automatic fault alarm functions, greatly reducing operation and maintenance difficulty.

Yes. We offer customizable fixtures that are compatible with round, flat, and various special-shaped wire harnesses. Whether you have special production requirements for automotive electronic harnesses or new energy battery pack harnesses, our team can design matching fixtures to ensure the machine fits your production line perfectly.

Thanks to the ±1℃ precision temperature control and uniform matrix heating module, the defect rate of our Heat Shrink Tube Baking Machine is controlled below 0.5%, which is much lower than the industry average (3%–5%). This can effectively reduce rework costs and improve your production efficiency.