- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Designed for businesses pursuing high-volume output without compromising on workplace noise control, this machine stands out as a top-tier solution for modern packaging workflows. Unlike traditional air cushion machines that generate disruptive noise during operation, the D80 integrates advanced mute technology to ensure a low-decibel working environment, while maintaining ultra-fast production speed to meet the tight packaging demands of e-commerce, precision manufacturing, and luxury goods sectors. It is optimized to produce high-quality air cushions that provide superior shock absorption, effectively safeguarding fragile and high-value items during transit. With its compact design and user-centric operation, the D80 becomes a must-have equipment for enterprises aiming to boost packaging efficiency and improve workplace comfort.

The D80 is built with a high-performance drive system that delivers blazing-fast cushion production, capable of meeting the high-volume packaging requirements of peak seasons such as shopping festivals. Its precision-engineered inflation and sealing mechanism ensures consistent output, eliminating delays caused by uneven inflation or material jams. This feature makes the machine ideal for large-scale e-commerce fulfillment centers and industrial assembly lines that require continuous and stable packaging supply.

Quiet performance is the core highlight of the D80 High-Speed Quiet Air Cushion Machine. It adopts a noise-dampening shell structure and a low-vibration internal component layout, reducing operational noise to an industry-leading level. This design is particularly beneficial for workshops and warehouses with strict noise restrictions, allowing workers to operate in a comfortable environment without affecting production efficiency.

The machine is equipped with an intuitive control panel that requires minimal training for operators to master. Its modular structure simplifies daily maintenance, with easily replaceable parts that cut down on downtime. Additionally, the D80 is compatible with most standard plastic films, offering flexible material options for different packaging scenarios.

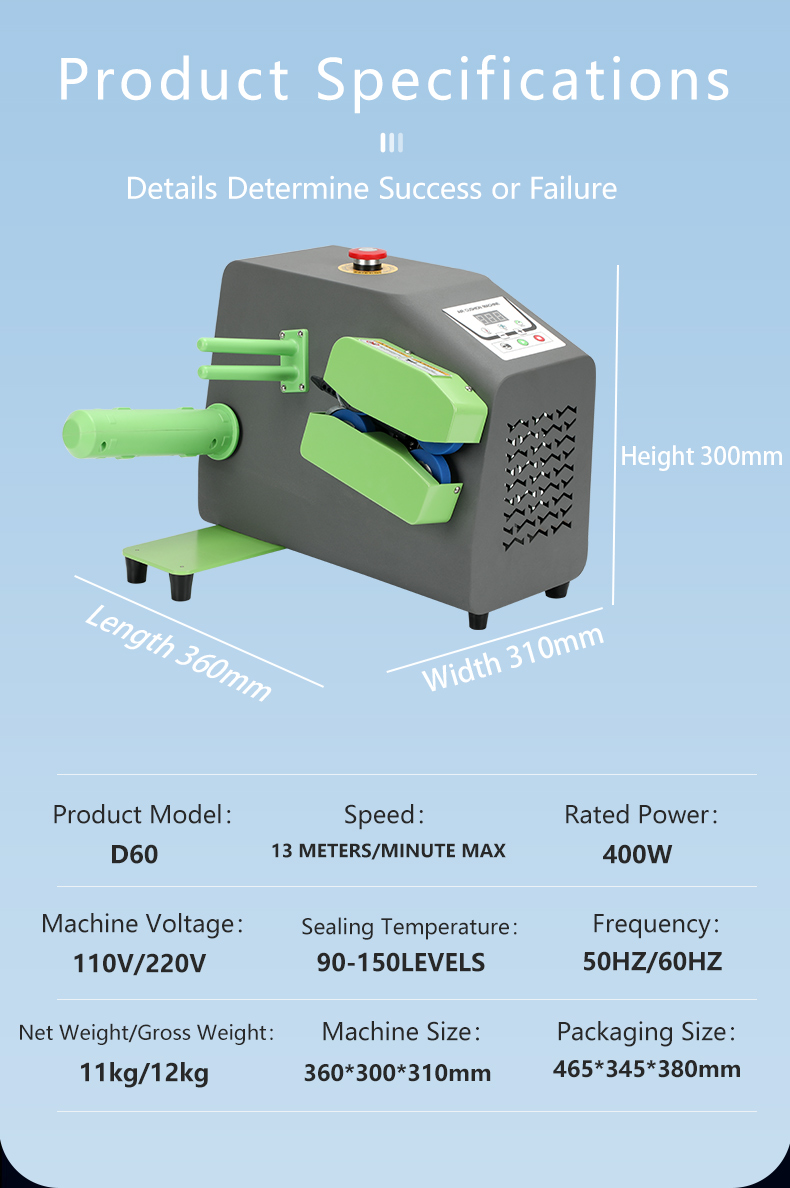

Specification Item | Parameter |

Model | D60 |

Frequency | 50HZ/60HZ |

Rated Power | 400W |

Machine Dimension | 360×300×310 mm |

Weight | 11 kg |

The D80’s high-speed production perfectly matches the massive packaging needs of e-commerce platforms during peak periods. It produces air cushions that effectively protect fragile items like glassware, electronics, and cosmetics, reducing transit damage rates and logistics costs.

For enterprises producing precision instruments and measuring tools, the machine’s quiet operation and stable cushion quality are critical. The air cushions provide gentle and comprehensive protection, preventing precision components from being damaged by vibration during transportation.

Luxury goods require both protective and aesthetically pleasing packaging. The D80 produces smooth, uniform air cushions that do not scratch high-end products such as leather goods, jewelry, and designer accessories, enhancing the unboxing experience for customers.

We are one of the few manufacturers that can achieve both high production speed and ultra-low noise levels in air cushion machines. The D80’s patented mute technology is tested and certified to meet international workplace noise standards.

We offer tailored film compatibility adjustments and control panel customization to meet the specific needs of different industries. Our professional team provides one-on-one technical support.

The D80 has a long service life with low energy consumption, reducing the overall operating costs for enterprises. We provide a 2-year warranty and on-site maintenance services to ensure long-term stable operation of the equipment.

Yes. The D80’s noise-dampening structure and heat-dissipating design ensure that the noise level remains stable at ≤ 55 dB even after 24 hours of continuous operation. The machine’s internal components are made of high-quality wear-resistant materials, avoiding noise increase caused by component wear.

Absolutely. The D80 has a compact size of 650×450×800 mm, which can be placed in small workshops or warehouse corners. Its lightweight design also allows for easy movement and position adjustment as needed.

The D80 is equipped with an intelligent film tension control system that automatically adjusts the film feeding speed according to production needs, minimizing film waste. Additionally, our after-sales team will provide training on film loading and operation skills to further reduce material waste.

Designed for businesses pursuing high-volume output without compromising on workplace noise control, this machine stands out as a top-tier solution for modern packaging workflows. Unlike traditional air cushion machines that generate disruptive noise during operation, the D80 integrates advanced mute technology to ensure a low-decibel working environment, while maintaining ultra-fast production speed to meet the tight packaging demands of e-commerce, precision manufacturing, and luxury goods sectors. It is optimized to produce high-quality air cushions that provide superior shock absorption, effectively safeguarding fragile and high-value items during transit. With its compact design and user-centric operation, the D80 becomes a must-have equipment for enterprises aiming to boost packaging efficiency and improve workplace comfort.

The D80 is built with a high-performance drive system that delivers blazing-fast cushion production, capable of meeting the high-volume packaging requirements of peak seasons such as shopping festivals. Its precision-engineered inflation and sealing mechanism ensures consistent output, eliminating delays caused by uneven inflation or material jams. This feature makes the machine ideal for large-scale e-commerce fulfillment centers and industrial assembly lines that require continuous and stable packaging supply.

Quiet performance is the core highlight of the D80 High-Speed Quiet Air Cushion Machine. It adopts a noise-dampening shell structure and a low-vibration internal component layout, reducing operational noise to an industry-leading level. This design is particularly beneficial for workshops and warehouses with strict noise restrictions, allowing workers to operate in a comfortable environment without affecting production efficiency.

The machine is equipped with an intuitive control panel that requires minimal training for operators to master. Its modular structure simplifies daily maintenance, with easily replaceable parts that cut down on downtime. Additionally, the D80 is compatible with most standard plastic films, offering flexible material options for different packaging scenarios.

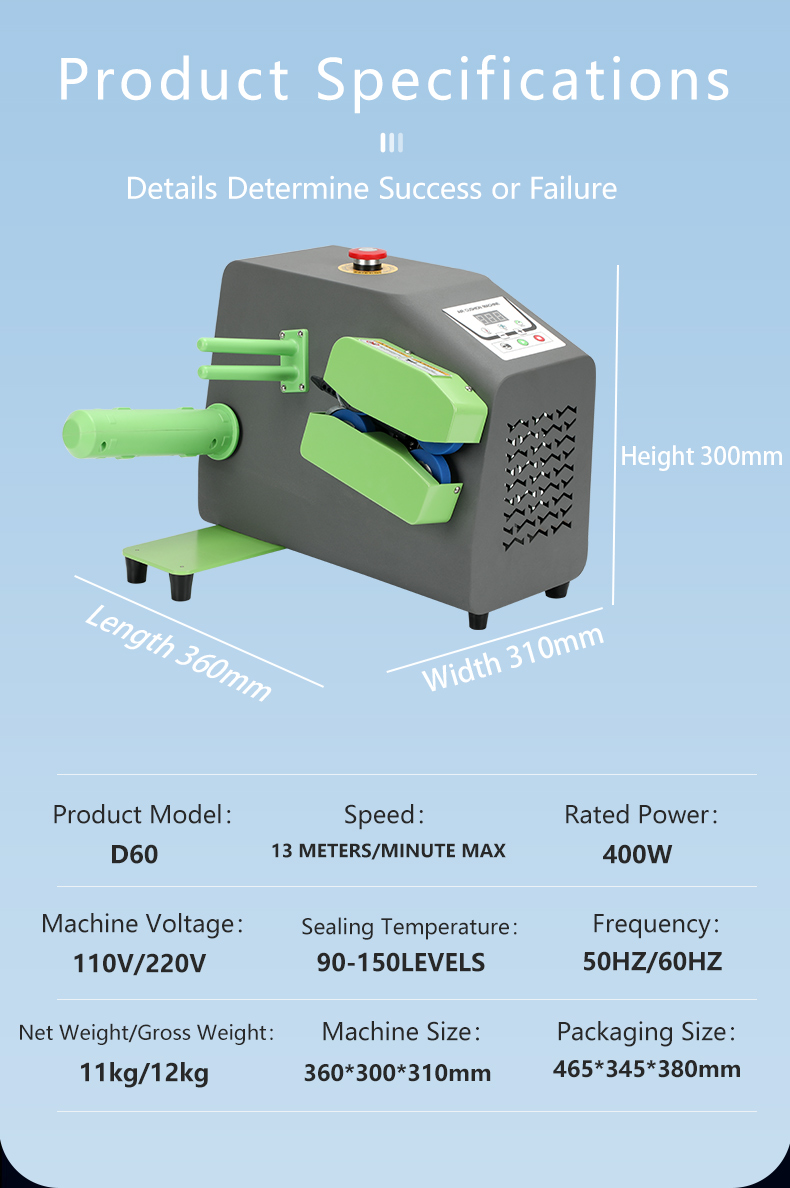

Specification Item | Parameter |

Model | D60 |

Frequency | 50HZ/60HZ |

Rated Power | 400W |

Machine Dimension | 360×300×310 mm |

Weight | 11 kg |

The D80’s high-speed production perfectly matches the massive packaging needs of e-commerce platforms during peak periods. It produces air cushions that effectively protect fragile items like glassware, electronics, and cosmetics, reducing transit damage rates and logistics costs.

For enterprises producing precision instruments and measuring tools, the machine’s quiet operation and stable cushion quality are critical. The air cushions provide gentle and comprehensive protection, preventing precision components from being damaged by vibration during transportation.

Luxury goods require both protective and aesthetically pleasing packaging. The D80 produces smooth, uniform air cushions that do not scratch high-end products such as leather goods, jewelry, and designer accessories, enhancing the unboxing experience for customers.

We are one of the few manufacturers that can achieve both high production speed and ultra-low noise levels in air cushion machines. The D80’s patented mute technology is tested and certified to meet international workplace noise standards.

We offer tailored film compatibility adjustments and control panel customization to meet the specific needs of different industries. Our professional team provides one-on-one technical support.

The D80 has a long service life with low energy consumption, reducing the overall operating costs for enterprises. We provide a 2-year warranty and on-site maintenance services to ensure long-term stable operation of the equipment.

Yes. The D80’s noise-dampening structure and heat-dissipating design ensure that the noise level remains stable at ≤ 55 dB even after 24 hours of continuous operation. The machine’s internal components are made of high-quality wear-resistant materials, avoiding noise increase caused by component wear.

Absolutely. The D80 has a compact size of 650×450×800 mm, which can be placed in small workshops or warehouse corners. Its lightweight design also allows for easy movement and position adjustment as needed.

The D80 is equipped with an intelligent film tension control system that automatically adjusts the film feeding speed according to production needs, minimizing film waste. Additionally, our after-sales team will provide training on film loading and operation skills to further reduce material waste.