- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Industrial Heat Shrink Tube Baking Machine | Multi-station Synchronous Heating, 20x Efficiency Boost for Wire Harness Processing

Key Advantages: Processes 20+ Workpieces at Once | Intelligent Temp Control ±1℃ | Suitable for Multi-Industry Wire Harness Processing

Solve Your Production Pain Points

Tired of low efficiency and high defect rates caused by manual baking or uneven heating? Traditional single-station equipment produces less than 500 pieces per shift with a 3%-5% defect rate, severely limiting your production line efficiency. Our Heat Shrink Tube Baking Machine redefines heat shrink processing standards with innovative technology, enabling "high-efficiency, precision, and stable" wire harness production for your business.

Core Features & Technical Highlights

· Multi-station Synchronous Heating: Innovative matrix heating module allows simultaneous baking of 20+ heat shrink tubes (diameter 5-20mm) at once, boosting efficiency by 20x compared to traditional equipment, with single-shift capacity exceeding 10,000 pieces.

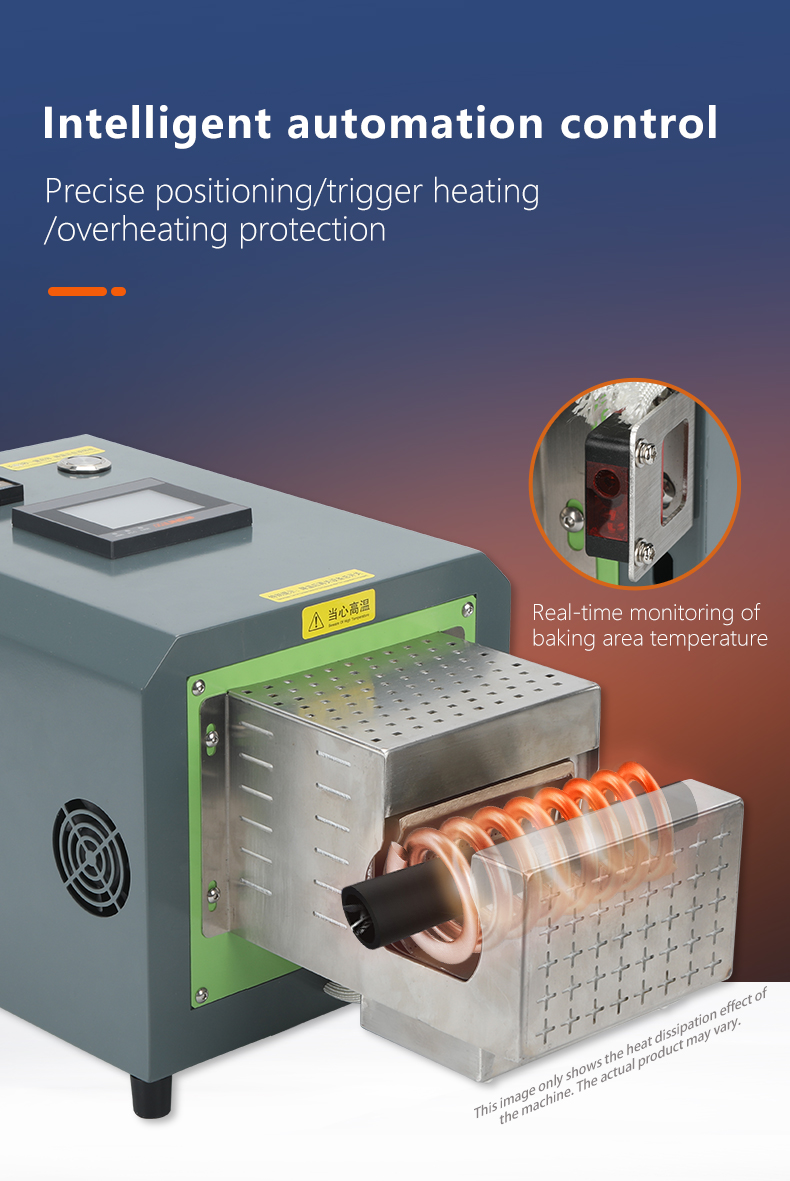

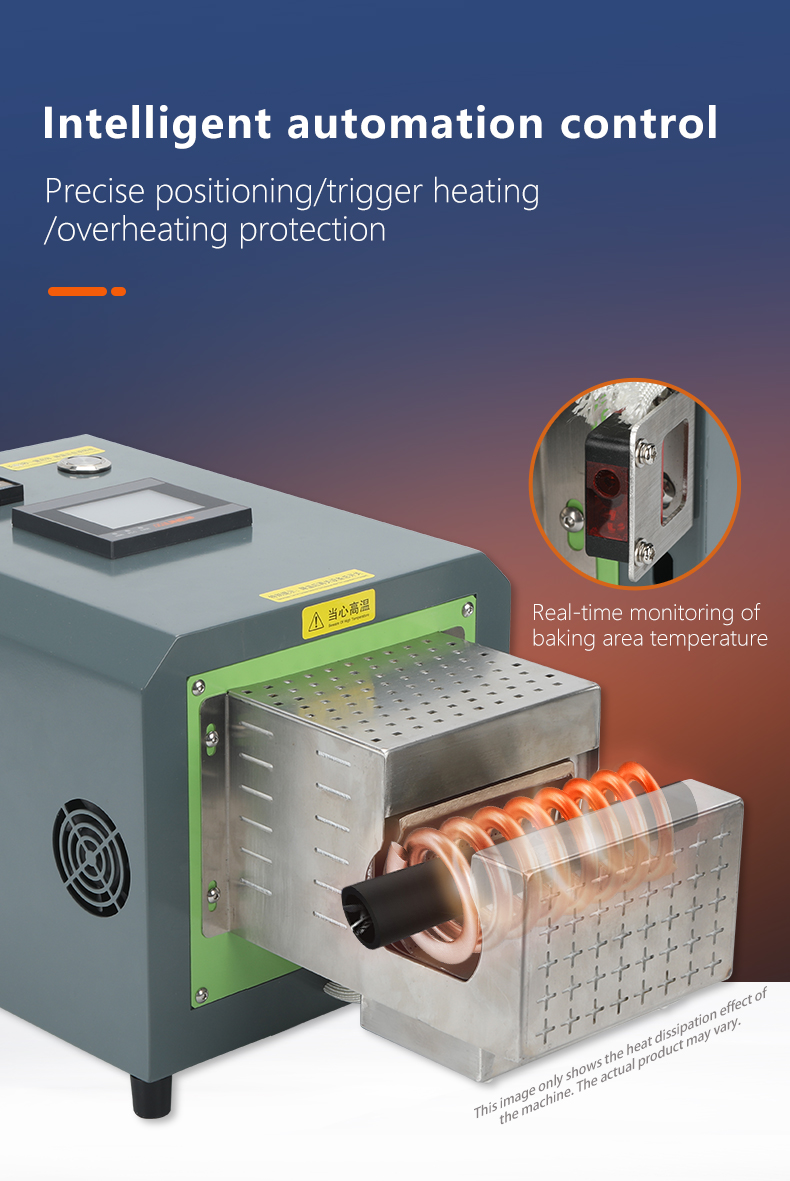

· Intelligent Temperature Control: Equipped with high-precision temperature sensors and PLC control system, real-time monitoring heating zone temperature with ±1℃ accuracy, ensuring heat shrink tubes are uniformly heated within the optimal 80-150℃ range, reducing defect rate to below 0.5%.

· Flexible Adaptability: Customizable fixtures compatible with round, flat, and other wire harness shapes, meeting flexible production needs in electronics, automotive, new energy, and other industries.

· User-Friendly Operation: Touchscreen visual interface for easy parameter setting, accessible even to new operators; real-time operation status display and automatic fault alarm reduce maintenance costs.

Why Choose Us?

✅ Efficiency Revolution: From "single manual operation" to "batch automation", directly driving production line capacity leap.

✅ Quality Assurance: Uniform heating technology eliminates heat shrink tube cracking and insufficient shrinkage, enhancing product reliability.

✅ Cost Optimization: Reduces labor input by 80%, cuts rework costs for defective products, and enables quick equipment investment recovery.

Applicable Industries: Automotive electronic wire harnesses, new energy battery pack harnesses, smart home connection harnesses, industrial control equipment harnesses, etc.

Take Action Now: Contact us for a customized solution and turn heat shrink tube baking into the "efficiency engine" of your production line!

Industrial Heat Shrink Tube Baking Machine | Multi-station Synchronous Heating, 20x Efficiency Boost for Wire Harness Processing

Key Advantages: Processes 20+ Workpieces at Once | Intelligent Temp Control ±1℃ | Suitable for Multi-Industry Wire Harness Processing

Solve Your Production Pain Points

Tired of low efficiency and high defect rates caused by manual baking or uneven heating? Traditional single-station equipment produces less than 500 pieces per shift with a 3%-5% defect rate, severely limiting your production line efficiency. Our Heat Shrink Tube Baking Machine redefines heat shrink processing standards with innovative technology, enabling "high-efficiency, precision, and stable" wire harness production for your business.

Core Features & Technical Highlights

· Multi-station Synchronous Heating: Innovative matrix heating module allows simultaneous baking of 20+ heat shrink tubes (diameter 5-20mm) at once, boosting efficiency by 20x compared to traditional equipment, with single-shift capacity exceeding 10,000 pieces.

· Intelligent Temperature Control: Equipped with high-precision temperature sensors and PLC control system, real-time monitoring heating zone temperature with ±1℃ accuracy, ensuring heat shrink tubes are uniformly heated within the optimal 80-150℃ range, reducing defect rate to below 0.5%.

· Flexible Adaptability: Customizable fixtures compatible with round, flat, and other wire harness shapes, meeting flexible production needs in electronics, automotive, new energy, and other industries.

· User-Friendly Operation: Touchscreen visual interface for easy parameter setting, accessible even to new operators; real-time operation status display and automatic fault alarm reduce maintenance costs.

Why Choose Us?

✅ Efficiency Revolution: From "single manual operation" to "batch automation", directly driving production line capacity leap.

✅ Quality Assurance: Uniform heating technology eliminates heat shrink tube cracking and insufficient shrinkage, enhancing product reliability.

✅ Cost Optimization: Reduces labor input by 80%, cuts rework costs for defective products, and enables quick equipment investment recovery.

Applicable Industries: Automotive electronic wire harnesses, new energy battery pack harnesses, smart home connection harnesses, industrial control equipment harnesses, etc.

Take Action Now: Contact us for a customized solution and turn heat shrink tube baking into the "efficiency engine" of your production line!